Comprehensive Generator Disassembly and Modernization in Austria

General overhaul of a power generation unit carried out by PRO-Welding in cooperation with Siemens

Project location: Austria

Contractor: PRO-Welding – a team of 11 certified specialists

Technology partner: Siemens

Scope of works: Comprehensive disassembly, modernization, and reassembly of the power generator

PRO-WELDING INDUSTRY SERVICES

PROJECT SCOPE

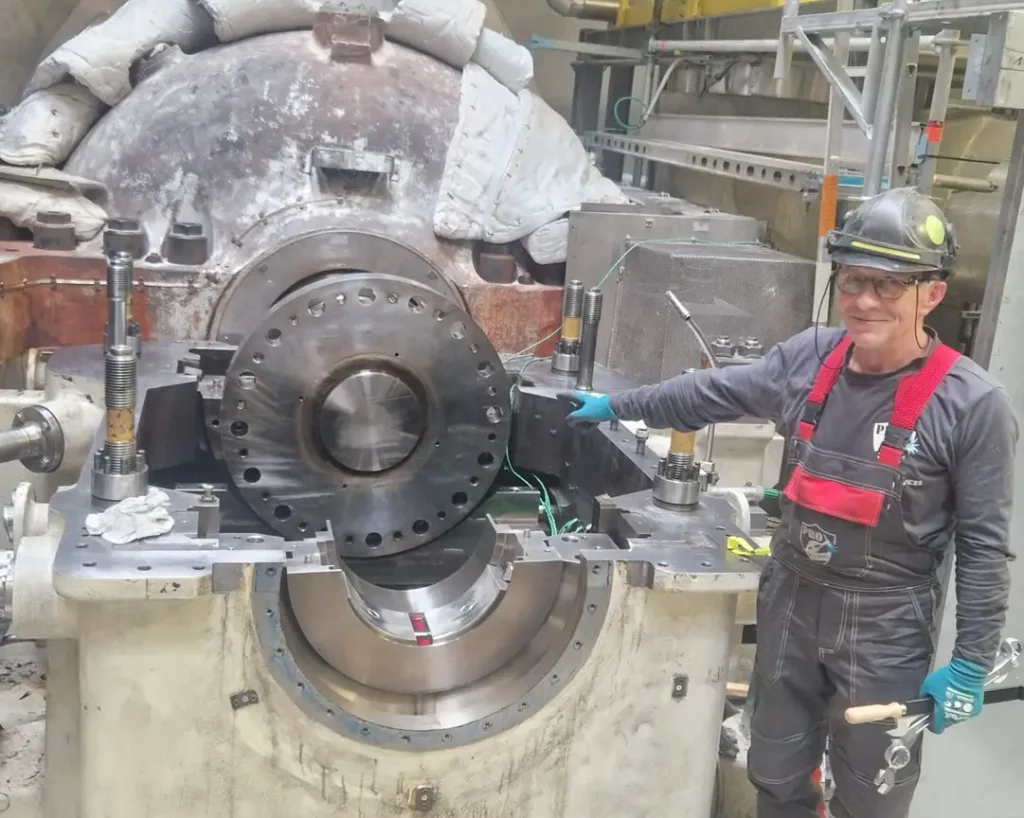

1. Comprehensive Generator Disassembly

The scope of work included the disassembly of casings, auxiliary systems, and all technological connections, providing safe access to the generator’s critical internal components.

The operation was carried out in stages, in full compliance with strict occupational health and safety procedures and technical documentation.

2. Shaft Line Works

The scope of work included the disassembly of the shafts connecting the integrated gas and steam turbine sections.

Ensuring subsequent coaxial alignment of such a complex system was one of the most challenging aspects of the project.

3. Rotor Replacement and Balancing

As part of the modernization, a new generator rotor was installed, followed by dynamic balancing of the entire assembly.

This process was critical for eliminating vibrations and ensuring stable operation at full rotational speed.

4. Cooling System Refurbishment and Leak Test

The generator cooling system was refurbished, followed by a leak test.

The positive test results confirmed the correctness of the executed works and the system’s readiness for operation.

Final Outcome

The works were completed with full success.

The generator equipped with the new rotor successfully passed load and dynamic tests, achieving operating parameters in full compliance with the manufacturer’s specifications.

PRO-WELDING INDUSTRY SERVICES

COOPERATION

Cooperation with Siemens was carried out at the highest organizational and technical level.

Close coordination between the engineering teams enabled the efficient execution of all project stages, despite the high level of operational complexity and the work being performed on a critical power generation unit.

The PRO-Welding team demonstrated a high level of technical competence, extensive experience, and excellent work organization, delivering the scope of works in accordance with the schedule and applicable quality and safety standards.

The project confirmed PRO-Welding’s capabilities in executing advanced modernizations and overhauls of power generation units in cooperation with global technology partners.

Looking for a reliable partner to deliver your project?

Contact us — we will prepare an offer tailored to your needs.