Comprehensive Replacement of the Superheater and Piping

Project location: Austria

Contractor: PRO-Welding Industry Services – team of 30 certified specialists

Scope of work: Replacement of the boiler superheater and roof tubes, taking into account high installation and logistical requirements while maintaining full technological discipline; TIG (141) welding.

PRO-WELDING INDUSTRY SERVICES

Project Stages and Key Challenges

1. Securing the Boiler Structure Geometry

The works commenced with a preparatory stage aimed at maintaining the integrity and geometry of the structure. Due to the risk of uncontrolled displacement of the headers resulting from the self-weight of the components and the release of stresses after dismantling the existing tubes, the following measures were applied:

- Locking and stiffening system – temporary fixations of the chambers were installed to ensure structural stability during dismantling and installation works.

- Sequential replacement – mass cutting of tubes was avoided in favor of phased replacement, which allowed the correct roof geometry to be maintained and ensured proper fitting of new components without introducing additional assembly stresses.

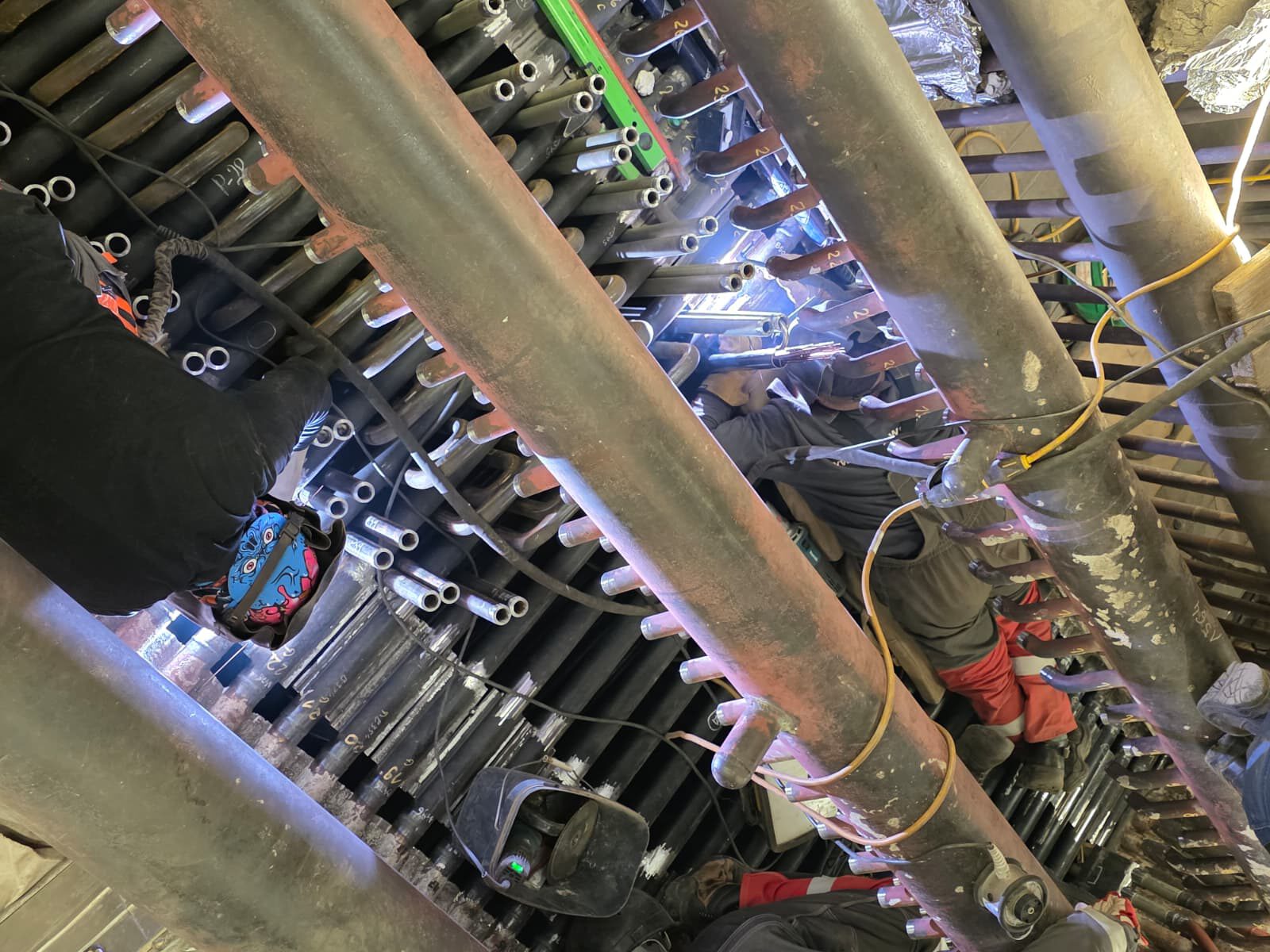

2. Work Organization in Confined Space Conditions

A key project challenge was the necessity to carry out works involving a large number of specialists within a very limited working space. Precise coordination of activities was therefore essential:

- Team management – a detailed schedule of access to workstations was developed for fitters, welders, and inspection (NDT) teams. Operating under this system made it possible to avoid clashes and downtime.

- Internal logistics – due to the lack of buffer space, the transport of coil components and materials was strictly synchronized with installation progress. Each logistical stage was planned to ensure maximum use of the available access routes.

3. Technological Discipline and Quality Control

Despite the short project timeline, the works were carried out with no compromise on execution quality:

- TIG (141) welding – the use of this technology enabled the achievement of welds with high strength and quality parameters, essential for pressure-bearing components.

- Full NDT control – 100% of the executed welded joints were subjected to radiographic testing (RT). The high qualifications of the team resulted in positive test results on the first attempt, which was crucial for maintaining the project schedule.

Copyright 2025 © All Right Reserved